A Guide to Automated Welding

In the right applications, automated welding can substantially improve the quality, productivity, and profitability of manufacturing operations. Despite this potential, the welding process is often overlooked or ignored while manufacturers integrate various other forms of automation into their processes. As welding automation technologies continue to become increasingly efficient, versatile, and affordable, having an understanding of them can help a manufacturing company remain competitive.

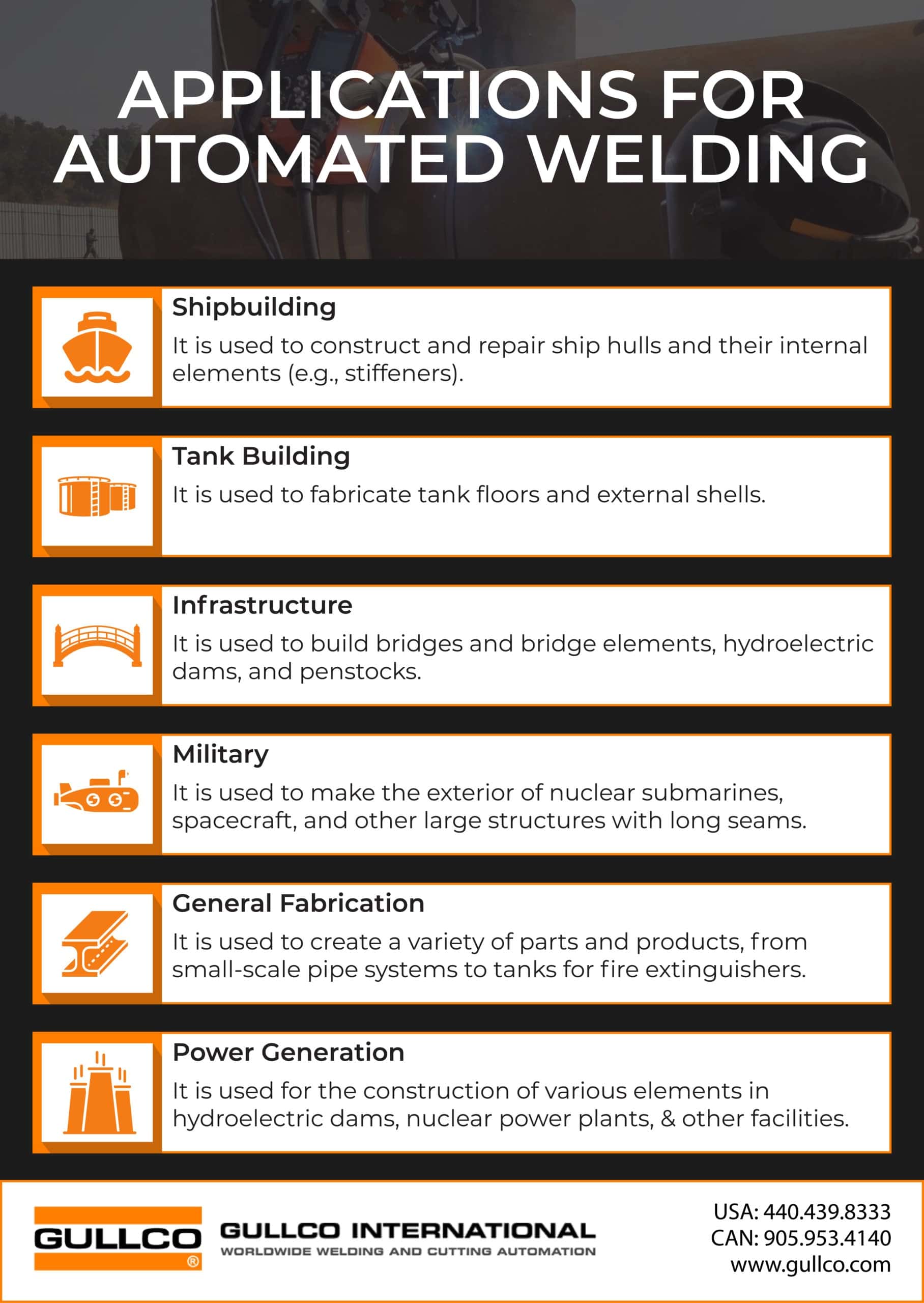

Below, we provide an overview of automated welding, outlining what it is, what benefits it offers, what applications it is used in, how to determine if it is right for you, and how it compares to other welding methods.

What Is Automated Welding?

Automated welding is a form of automatic welding that uses electronically controlled tools and equipment to handle and welding applications with minimal human oversight. Interfaced with the welding power supply and wire feeders, the tools and equipment allow for precise manipulation of each welding parameter and close monitoring of weld performance. This level of precision and control can improve productivity, reduce defects, and decrease overall production costs. Typically, the process is used in easily repeatable processes with high volume.

Automated welding is a form of automatic welding that uses electronically controlled tools and equipment to handle and welding applications with minimal human oversight. Interfaced with the welding power supply and wire feeders, the tools and equipment allow for precise manipulation of each welding parameter and close monitoring of weld performance. This level of precision and control can improve productivity, reduce defects, and decrease overall production costs. Typically, the process is used in easily repeatable processes with high volume.