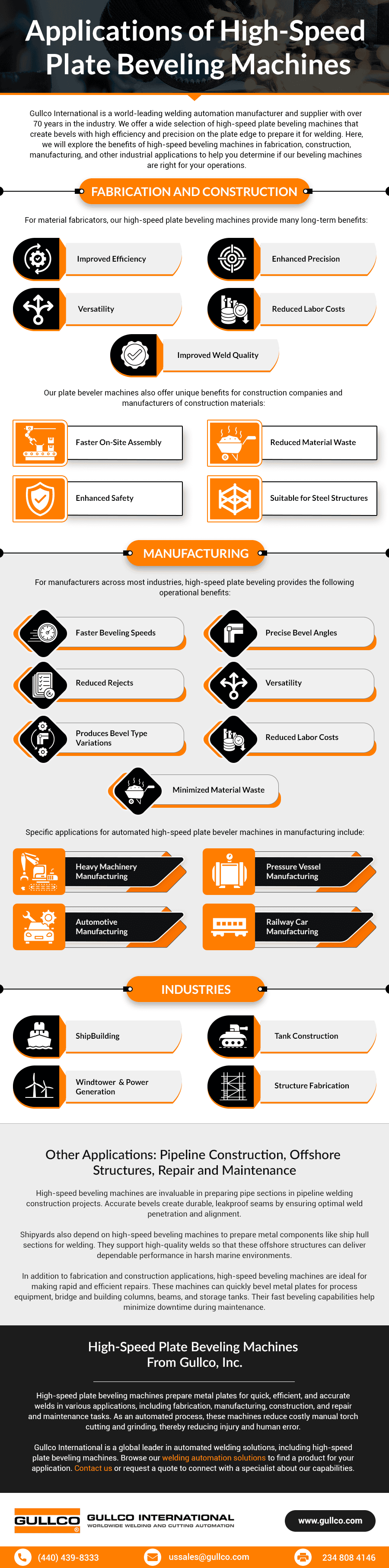

Applications of High-Speed Plate Beveling Machines

Gullco International is a world-leading welding automation manufacturer and supplier with over 70 years in the industry. We offer a wide selection of high-speed plate beveling machines that create bevels with high efficiency and precision on the plate edge to prepare it for welding. Here, we will explore the benefits of high-speed beveling machines in fabrication, construction, manufacturing, and other industrial applications to help you determine if our beveling machines are right for your operations.

Fabrication and Construction

For material fabricators, our high-speed plate beveling machines provide many long-term benefits:

- Improved Efficiency: Compared to manual beveling methods, such as torch cutting and grinding, high-speed plate beveling minimizes preparation time. It supports increased output and expedites project completion.

- Enhanced Precision: High-speed plate beveling machines provide accurate, consistent beveling from end to end of the plate edge. Such consistency and precision are critical to creating superior-quality welds and reducing the need for rework.

- Versatility: Our plate beveling machines can accommodate a wide range of thicknesses and fabrication materials, including aluminum, stainless steel, and mild steel. They can also create a variety of bevel types, including U, V, and K bevels to suit different welding applications.

- Reduced Labor Costs: Automating the beveling process reduces the need for costly manual labor, resulting in long-term cost savings.

- Improved Weld Quality: Accurate bevels facilitate proper weld penetration and metal joining, producing durable and high-strength welding joints.

Our plate beveler machines also offer unique benefits for construction companies and manufacturers of construction materials:

- Faster On-Site Assembly: Portable high-speed beveling machines can be used at the construction site itself. Thus, construction crews don’t need to rely exclusively on pre-beveled components from offsite workshops, facilitating rapid on-site assembly and shorter project timelines.

- Reduced Material Waste: High-speed plate beveling machines create a precise and clean bevel compared to traditional methods. They also minimize material waste from the cutting process.

- Enhanced Safety: Automating beveling applications minimizes the risk of injuries that would be associated with manual beveling.

- Suitable for Steel Structures: High-speed plate beveler machines are essential in preparing steel components like columns and beams for welding structures such as buildings and bridges.

Manufacturing

For manufacturers across most industries, high-speed plate beveling provides the following operational benefits:

- Faster Beveling Speeds: Automated, high-speed plate beveling machines considerably reduce the time spent beveling plates compared to traditional torch-cutting and grinding methods. They can deliver higher production outputs and increase processing rates, making them ideal for large-volume plate processing.

- Precise Bevel Angles: High-speed plate beveler machines provide a precise and consistent bevel from one end of the plate edge to the other, meeting exact weld specifications. Improved precision is essential to optimal weld fusion and penetration, which produces strong and dependable end products.

- Reduced Rejects: Consistent beveling through automation minimizes worker fatigue and errors that can produce rejected components. It can deliver defect-free products with less rework and higher yields.

- Versatility: High-speed plate beveling machines can accommodate various manufacturing materials—including aluminum, stainless steel, and steel—and plate thicknesses. The flexibility of high-speed beveling allows the machines to seamlessly integrate into most production lines.

- Produces Bevel Type Variations: Advanced high-speed beveling machines can accommodate various bevel types, including K, U, and V types depending on the welding application.

- Reduced Labor Costs: Automated high-speed plate beveler machines reduce the need for traditional grinding and torch-cutting processes. The machines can be operated with fewer operators and provide long-term savings.

- Minimized Material Waste: High-speed plate beveling machines deliver clean and precise bevels compared to traditional methods. They reduce material waste from manual cutting, improving sustainability and reducing material expenses.

Specific applications for automated high-speed plate beveler machines in manufacturing include:

- Heavy Machinery Manufacturing: High-speed beveling machines are critical in preparing thick steel plates for heavy machinery, construction, and mining equipment fabrication.

- Pressure Vessel Manufacturing: Pressure vessels require precisely beveled plates to meet the requirements of the oil and gas and chemical processing industries.

- Automotive Manufacturing: The automotive industry relies on high-speed plate beveling machines to prepare chassis components, frames, and other structural components before welding.

- Railway Car Manufacturing: Automated beveling delivers quality welds for the construction of transportation vehicles and railway cars.

Other Applications: Pipeline Construction, Offshore Structures, Repair and Maintenance

High-speed beveling machines are invaluable in preparing pipe sections in pipeline welding construction projects. Accurate bevels create durable, leakproof seams by ensuring optimal weld penetration and alignment.

Shipyards also depend on high-speed beveling machines to prepare metal components like ship hull sections for welding. They support high-quality welds so that these offshore structures can deliver dependable performance in harsh marine environments.

In addition to fabrication and construction applications, high-speed beveling machines are ideal for making rapid and efficient repairs. These machines can quickly bevel metal plates for process equipment, bridge and building columns, beams, and storage tanks. Their fast beveling capabilities help minimize downtime during maintenance.

High-Speed Plate Beveling Machines From Gullco, Inc.

High-speed plate beveling machines prepare metal plates for quick, efficient, and accurate welds in various applications, including fabrication, manufacturing, construction, and repair and maintenance tasks. As an automated process, these machines reduce costly manual torch cutting and grinding, thereby reducing injury and human error.

Gullco International is a global leader in automated welding solutions, including high-speed plate beveling machines. Browse our welding automation solutions to find a product for your application. Contact us or request a quote to connect with a specialist about our capabilities.